Circular Plastics

Our Canadian circular system for recycled HDPE fishing gear avoids impact on climate change by 92%, on water scarcity by 95% and on ecosystem quality by 87%, in comparison to virgin plastics produced in China.

For every tonne recycled, we avoid 1.96 tonnes of crude oil.

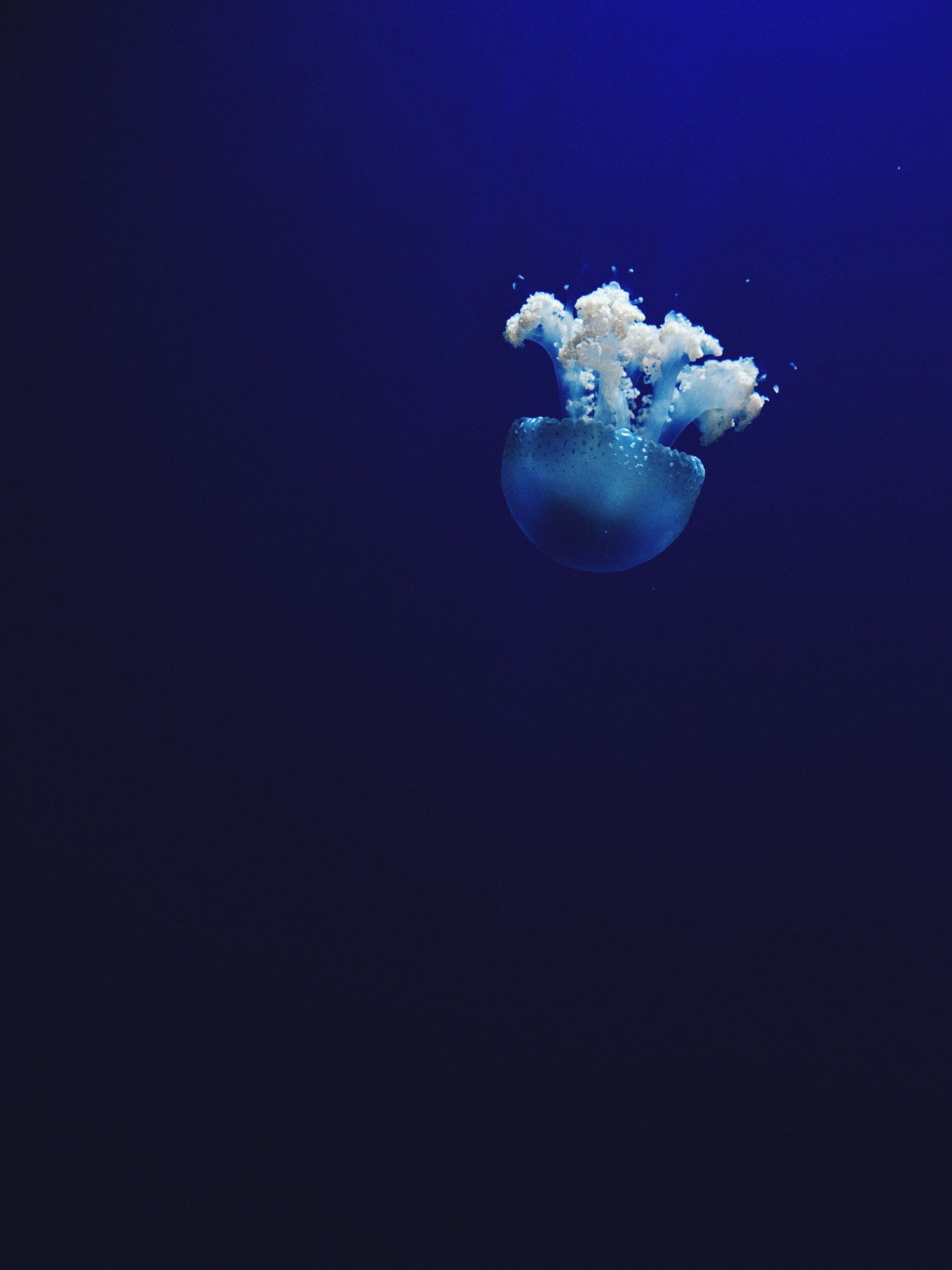

There are many challenges in recycling abandoned, lost and discarded fishing gear. Some of these challenges include waste management once gear has been collected, washing and decontamination of materials, and clear identification of mixed materials prior to recycling. Streamlining the process from waste management to recycling ensures we can transform old waste into new products, while retaining quality and strength. Innovation in advanced recycling processes can pave the way to a Net Zero emissions economy while giving the ocean the opportunity to restore its natural ecosystem.

At Polytechnique Montreal, our research team has pioneered circular solutions to tackle these challenges. We've demonstrated the feasibility of recycling processes for some of the most challenging materials that can’t be recycled globally. We turned these “impossible” materials into recycled pellets suitable for manufacturing endless types of plastic products made by injection molding and 3D printing. In our commitment to eliminating greenwashing and developing science based tools for decision making we collaborated with the CIRAIG to conduct a Life Cycle Analysis (LCA) of our Canadian recycling system. By continuously innovating with our network, one project at a time, we are making the impossible possible.

Let’s work together.

Looking to incorporate 100% recycled plastic from fishnets into your products? Contact us today!